LISA WMS

FOR SAP BUSINESS ONE & SAP BUSINESS BYDESIGN

THE MOST EFFECTIVE BARCODE SCANNING SYSTEM TO GAIN CONTROL OVER YOUR INVENTORY

LISA WMS

FOR SAP BUSINESS ONE & SAP BUSINESS BYDESIGN

THE MOST EFFECTIVE BARCODE SCANNING SYSTEM TO GAIN CONTROL OVER YOUR INVENTORY

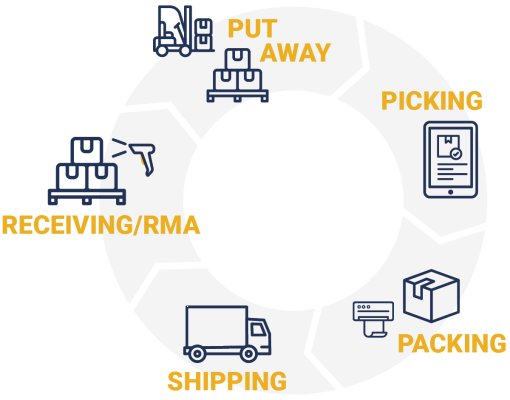

RECEIVE, PICK, PACK AND SHIP ORDERS FASTER WITH COMPLETE TRACEABILITY AND REAL-TIME VISIBILITY

LISA WMS is a Warehouse Management Software and Barcode Scanning System designed to automate and optimize warehouse operations in a paperless environment. LISA WMS is SAP-Certified for SAP Business One, and one of the only WMS designed with maximal compatibility with SAP Business ByDesign.

With LISA WMS, wholesale distributors and manufacturers can streamline the inbound and outbound supply chain, optimize warehouse space, enable profitable omnichannel distribution, track inventory in real time, and even implement the most advanced warehouse automation technologies available for small and midsize businesses.

Achieve Real-Time Inventory Data Accuracy

Most of our clients achieve 99.9% inventory accuracy after the first year of using their new warehouse management system with barcoding.

Boost Workforce Productivity & Efficiency

Automate manual operations, optimize employee downtime and guide new and experienced operators as they put products away or fulfill orders.

End-to-End Traceability & Easy Compliance

Easily track lots, batches, serial numbers as well expiration dates through advanced barcoding technologies such as GS1, GTIN…

Deliver a Better Customer Experience

Accelerate order fulfillment, eliminate shipping errors and integrate with ecommerce platforms, EDI and market places.

Optimize Space in Complex Warehouse Environments

Manage bins, locations for fast-moving items, inventory transfers between warehouses and items using the right strategies (FIFO, LIFO…)

Leverage True Supply Chain Innovation

Deploy affordable, yet powerful next-gen warehouse automation technologies to drive profitable growth, such as pick-to-lights, AR glasses, collaborative robots and more!

Successfully deployed in hundreds of SMBs using SAP Business One & ByDesign

LISA WMS is a globally trusted solution, successfully deployed across hundreds of Small and Medium-sized Business (SMB) using SAP Business One and SAP Business ByDesign spanning six continents.

LISA is available in six languages, ensuring seamless operations and user experience worldwide.

Supported Languages

English – Spanish – French – German – Portuguese – Dutch

LISA WMS for SAP Business One Delivers a Clear and Rapid ROI,

Making it a Critical Priority for any Company Operating One or Multiple Warehouses

Reduce Operational Costs

By automating manual tasks, eliminating paper-based operations and optimizing workflows, a WMS significantly reduces labor and operational costs.

Boost Cashflows and Sales

With accurate inventory updated in real time, you can forecast demand better, optimize inventory turnover, prevent stockouts, and minimize overstocking.

Eliminate Returns and Make Happier Customers

LISA WMS’ warehouse automation capabilities reduces lead time and picking errors, which decreases returns and improves customer satisfaction and loyalty.

Key SAP Business One WMS Features Delivered by LISA WMS

LISA WMS extends SAP Business One powerful functionality throughout the inbound and outbound supply chain.

Barcode Scanning and Labels Printing

LISA WMS leverages barcode scanning and RF (radio frequency) technology to eliminate manual data entry, significantly reduce errors, and provide real-time tracking of inventory throughout the entire supply chain. By integrating seamlessly with SAP Business One, the system enables users to generate and print customized barcodes and labels tailored to specific operational needs. This ensures that every item, pallet, or shipment is accurately identified and easily traceable at every stage of the warehouse process.

Our warehouse management system supports a wide range of advanced barcoding formats, including 2D, data matrix, GS1, and GTI, delivering flexible and robust solutions for businesses with diverse requirements. The result is improved inventory accuracy, streamlined operations, and enhanced visibility and control across your warehouse.

Barcode Scanning and Labels Printing

LISA WMS leverages barcode scanning and RF (radio frequency) technology to eliminate manual data entry, significantly reduce errors, and provide real-time tracking of inventory throughout the entire supply chain. By integrating seamlessly with SAP Business One, the system enables users to generate and print customized barcodes and labels tailored to specific operational needs. This ensures that every item, pallet, or shipment is accurately identified and easily traceable at every stage of the warehouse process.

Our warehouse management system supports a wide range of advanced barcoding formats, including 2D, data matrix, GS1, and GTI, delivering flexible and robust solutions for businesses with diverse requirements. The result is improved inventory accuracy, streamlined operations, and enhanced visibility and control across your warehouse.

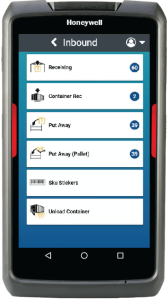

Receiving and Guided Put-Away

LISA WMS streamlines and optimizes the entire inbound logistics process, from the moment a truck or container arrives at the warehouse to the putting-away of inventory on shelves. As shipments are unloaded, the system ensures that every step, from receiving and documenting purchase orders to stock placement, is carried out efficiently and accurately.

Upon arrival, goods are scanned devices or scanners integrated with LISA WMS, which immediately cross-checks each item against the original purchase order data. This automatic verification not only reduces manual errors but also ensures that only the correct quantities and items are received. The software even calculates the most efficient route through the warehouse to save time and reduce travel distance. LISA WMS ensures a faster, smarter, and more reliable put-away process, laying a strong foundation for all warehouse operations.

Receiving and Guided Put-Away

LISA WMS streamlines and optimizes the entire inbound logistics process, from the moment a truck or container arrives at the warehouse to the putting-away of inventory on shelves. As shipments are unloaded, the system ensures that every step, from receiving and documenting purchase orders to stock placement, is carried out efficiently and accurately.

Upon arrival, goods are scanned devices or scanners integrated with LISA WMS, which immediately cross-checks each item against the original purchase order data. This automatic verification not only reduces manual errors but also ensures that only the correct quantities and items are received. The software even calculates the most efficient route through the warehouse to save time and reduce travel distance. LISA WMS ensures a faster, smarter, and more reliable put-away process, laying a strong foundation for all warehouse operations.

Inventory Management & Warehouse Configuration

LISA WMS empowers warehouse/supply chain managers to configure and organize warehouse space for maximum efficiency by allowing precise control and visibility at every level—from bin and zone to site, warehouse, and 3PL operations. The system enables fast, accurate inventory searches using advanced location tracking, so users can instantly locate any item within the warehouse network. With support for dynamic replenishment, LISA WMS automatically monitors stock levels and triggers restocking tasks to maintain optimal inventory, ensuring that high-demand items are always available. Additionally, FIFO (First-In, First-Out) and FEFO (First-Expired, First-Out) strategies are built in, guiding operators to pick products according to receipt date or expiration, minimizing waste and maintaining product quality. This comprehensive approach streamlines inventory management, reduces search times, and maximizes warehouse utilization.

Inventory Management & Warehouse Configuration

LISA WMS empowers warehouse/supply chain managers to configure and organize warehouse space for maximum efficiency by allowing precise control and visibility at every level—from bin and zone to site, warehouse, and 3PL operations. The system enables fast, accurate inventory searches using advanced location tracking, so users can instantly locate any item within the warehouse network. With support for dynamic replenishment, LISA WMS automatically monitors stock levels and triggers restocking tasks to maintain optimal inventory, ensuring that high-demand items are always available. Additionally, FIFO (First-In, First-Out) and FEFO (First-Expired, First-Out) strategies are built in, guiding operators to pick products according to receipt date or expiration, minimizing waste and maintaining product quality. This comprehensive approach streamlines inventory management, reduces search times, and maximizes warehouse utilization.

Order Picking, Packing, and Fulfillment

LISA WMS optimizes the entire picking, packaging, and order fulfillment process to ensure accuracy, efficiency, and speed. The system generates optimized picking lists and routes based on real-time inventory data and warehouse layout, guiding operators to the correct locations and minimizing travel time. During picking, barcode scanning verifies that the right items and quantities are selected, drastically reducing errors and ensuring order accuracy. Once picked, operators are guided through the packaging process, with the system providing instructions to select the appropriate packaging materials and print shipping labels as needed. This seamless workflow—from picking to packaging and final order confirmation—enables faster order fulfillment, lowers the risk of shipping mistakes, and enhances customer satisfaction, all while providing real-time visibility into order status and inventory levels.

Order Picking, Packing, and Fulfillment

LISA WMS optimizes the entire picking, packaging, and order fulfillment process to ensure accuracy, efficiency, and speed. The system generates optimized picking lists and routes based on real-time inventory data and warehouse layout, guiding operators to the correct locations and minimizing travel time. During picking, barcode scanning verifies that the right items and quantities are selected, drastically reducing errors and ensuring order accuracy. Once picked, operators are guided through the packaging process, with the system providing instructions to select the appropriate packaging materials and print shipping labels as needed. This seamless workflow—from picking to packaging and final order confirmation—enables faster order fulfillment, lowers the risk of shipping mistakes, and enhances customer satisfaction, all while providing real-time visibility into order status and inventory levels.

Shipping Logistics

After orders are packed, the system automatically verifies the contents and matches them to the correct shipping documents, ensuring each package is ready for dispatch. Operators receive guided instructions to select the appropriate carrier and shipping method based on order requirements, destination, and customer preferences. LISA WMS generates and prints shipping labels, tracks shipments in real time, and updates order status within SAP Business One. By automating documentation, reducing manual entry, and providing end-to-end visibility, LISA WMS helps ensure that shipments are dispatched accurately and on time, minimizing delays and improving overall customer satisfaction.

Shipping Logistics

After orders are packed, the system automatically verifies the contents and matches them to the correct shipping documents, ensuring each package is ready for dispatch. Operators receive guided instructions to select the appropriate carrier and shipping method based on order requirements, destination, and customer preferences. LISA WMS generates and prints shipping labels, tracks shipments in real time, and updates order status within SAP Business One. By automating documentation, reducing manual entry, and providing end-to-end visibility, LISA WMS helps ensure that shipments are dispatched accurately and on time, minimizing delays and improving overall customer satisfaction.

Warehouse Workforce Management

Labor is the highest cost in most warehouses and distribution centers. LISA WMS is a phenomenal tool to increase the productivity and efficiency of your warehouse team while greatly reducing errors cased by human interactions. By leveraging system-directed put-away and order picking, LISA WMS eliminates reliance on tribal knowledge and significantly shortens the training time needed for new employees to reach full productivity. The system intelligently assigns cycle counting and other inventory management tasks to idle operators, ensuring optimal use of available labor and reducing downtime. Additionally, LISA WMS offers comprehensive employee performance monitoring through real-time KPIs and productivity metrics, enabling managers to identify top performers, address bottlenecks, and continuously improve team efficiency. This data-driven approach streamlines workforce management, reduces labor costs, and enhances the overall performance of warehouse operations.

Warehouse Workforce Management

Labor is the highest cost in most warehouses and distribution centers. LISA WMS is a phenomenal tool to increase the productivity and efficiency of your warehouse team while greatly reducing errors cased by human interactions. By leveraging system-directed put-away and order picking, LISA WMS eliminates reliance on tribal knowledge and significantly shortens the training time needed for new employees to reach full productivity. The system intelligently assigns cycle counting and other inventory management tasks to idle operators, ensuring optimal use of available labor and reducing downtime. Additionally, LISA WMS offers comprehensive employee performance monitoring through real-time KPIs and productivity metrics, enabling managers to identify top performers, address bottlenecks, and continuously improve team efficiency. This data-driven approach streamlines workforce management, reduces labor costs, and enhances the overall performance of warehouse operations.

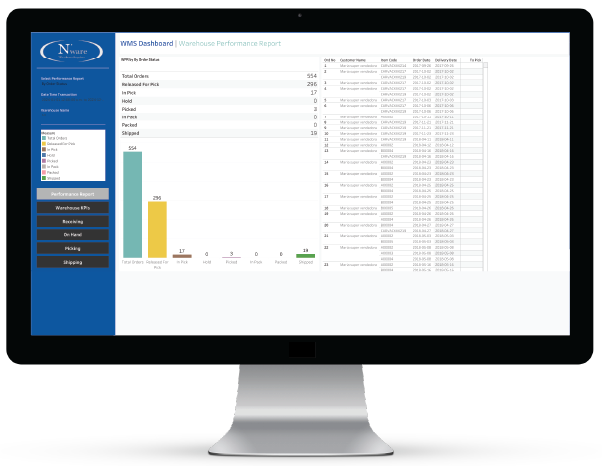

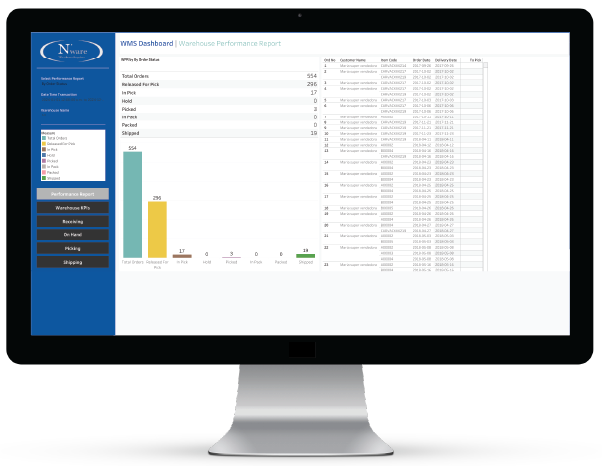

Warehouse Performance Analytics

LISA WMS delivers robust warehouse analytics that provides real-time visibility into every aspect of your warehouse operations. The system collects and analyzes data on inventory levels, order fulfillment rates, picking accuracy, and employee productivity, transforming this information into actionable insights through intuitive dashboards and detailed reports. Executives can monitor key performance indicators (KPIs) such as order cycle times, inventory turnover, space utilization, and labor efficiency, allowing them to quickly identify trends, spot inefficiencies, and make data-driven decisions.

With customizable reporting tools powered by N’Sight for SAP Business One, LISA WMS empowers warehouse and supply chain managers to track progress against business goals, optimize processes, and respond proactively to changing demands. By leveraging advanced analytics, companies can continuously improve warehouse performance, reduce costs, and enhance customer satisfaction.

Warehouse Performance Analytics

LISA WMS delivers robust warehouse analytics that provides real-time visibility into every aspect of your warehouse operations. The system collects and analyzes data on inventory levels, order fulfillment rates, picking accuracy, and employee productivity, transforming this information into actionable insights through intuitive dashboards and detailed reports. Executives can monitor key performance indicators (KPIs) such as order cycle times, inventory turnover, space utilization, and labor efficiency, allowing them to quickly identify trends, spot inefficiencies, and make data-driven decisions.

With customizable reporting tools powered by N’Sight for SAP Business One, LISA WMS empowers warehouse and supply chain managers to track progress against business goals, optimize processes, and respond proactively to changing demands. By leveraging advanced analytics, companies can continuously improve warehouse performance, reduce costs, and enhance customer satisfaction.

Compatibility LISA WMS for SAP Business One & SAP Business ByDesign

- SAP Certified for SAP Business One

- Compatible with SAP Business ByDesign

- Browser-based and fully decoupled

- Integrates with SAP Business One’s Web Clien

- Compatible with almost any device, computer or mobile/handheld scanners

N.B. LISA WMS CAN be integrated with other solutions, but it is not part of our core product. If you are seriously interested in integration our advanced barcode scanning software with another ERP, simply reach out to our team!